A Quick Summary of the Idea behind Norm:

The New Normal in Landscaping

My pursuit of Artificial Intelligence eventually led into my passion for Robotics.

At the end of 2018 I started forming an idea for a robot that I wanted to build. After consulting with some of my favorite professors, I began my pursuit of building my very own robot.

One day in my final year, as I was forced to listen to a large University Lawn Mower outside of my little appartment, I asked myself: why is it was so loud? why is ran on gasoline? and why did a human have to drive it?

These questions popped into my mind every time I heard the mower, and eventually I decided that I wanted to make a mower that was not plauged by any of these issues. After consulting with my favorite professors, I began my pursuit of

building my own Autonomous Landscaping Robot. Norm's design draws from my experience as a farm hand and landscaper during my High School years, using these experiences I began researching into the current designs of machines in the landscaping and farming industry.

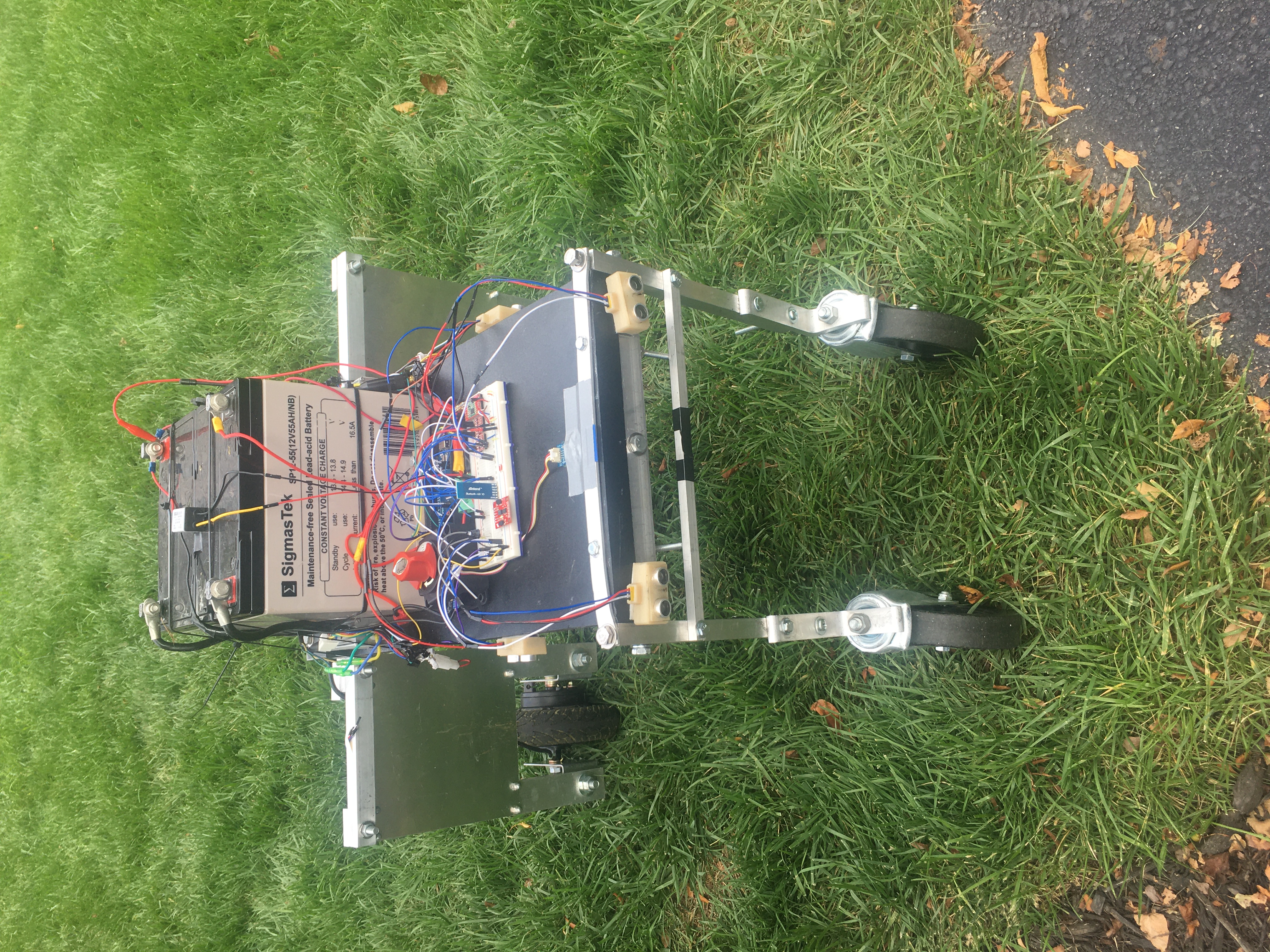

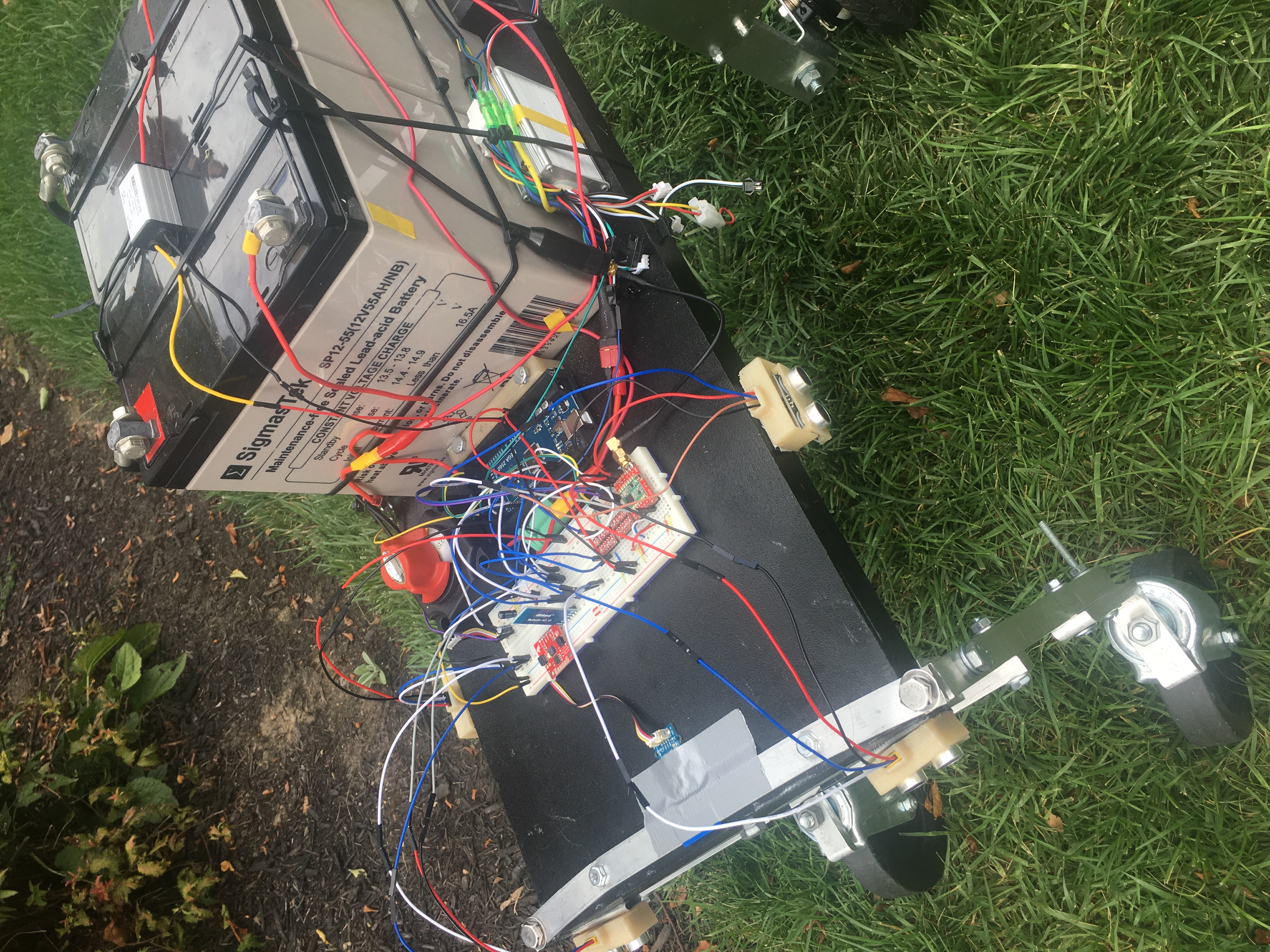

In the year since I've began, Norm is still in its Beta but has come a long way. Here is of List of all of the pieces used in making Norm Work:

- Build Materials

- High Quality Aluminium Frame

- HDPE Main Body Panel

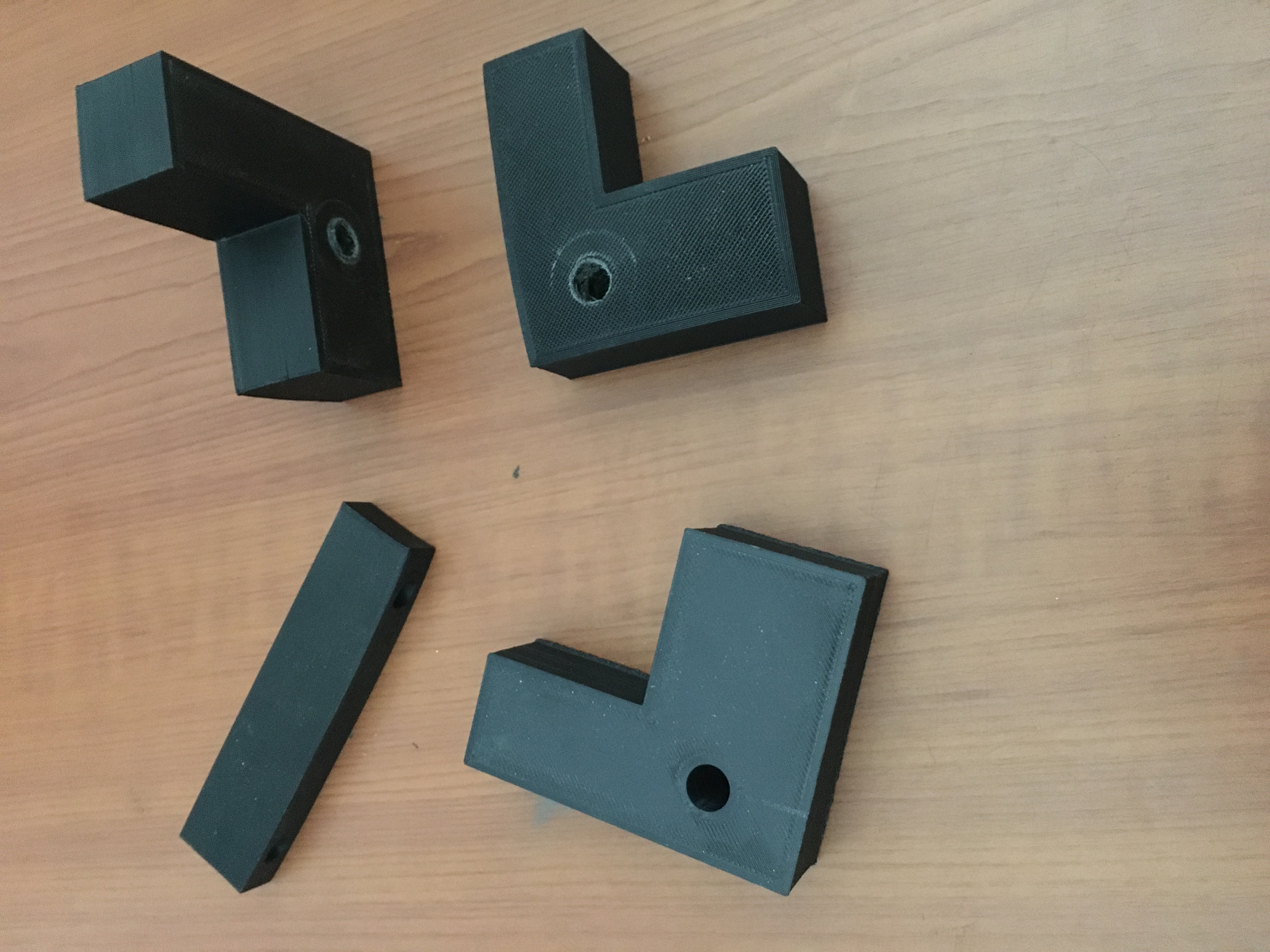

- 3D Printed Parts: Carbon Fiber, Nylon 6/6, and ABS

- Technologies

- Radio Communicatoin

- Bluetooth Communication

- Distance Sensors: Sonar and Infared

- Brushless Gearless Electric DC Motors

- Satellite Imaging

- Deep Learning

- 10-DOF Inertial Measurement Unit

- GPS and GNSS Location Technology

- Spectrometer and Light Sensors

- an 8-bit Microcontroller

my design philophy for Norm was to keep it simple. I want him to be easy to repair and cheap to produce right here in the United States. Norm is currently only using an 8-bit processor, this was decided as both a challenge and cost saving measure. I know that if it can work on a simple processor, that upgrading will give great performance benefits for his final version.

Pictures of Norm

Iterations of 3D Printed Part Designs